3D microcrystalline-glass?ceramic?tile machine

- Product Details

- Company Profile

3D microcrystalline-glass?ceramic?tile machine

Product feature

3D microcrystalline-glass ceramic tile is a composite of ceramic tile and the microcrystalline-glass (which has been printed personalized graphics by 3D high-definition printer first)in vacuum and high temperature. And then grind edge and anti-skid to be finised3D microcrystalline-glass ceramic tile is a composite of ceramic tile and the microcrystalline-glass (which has been printed personalized graphics by 3D high-definition printer first )in vacuum and high temperature. And then grind edge and anti-skid to be finised

1.The three-dimensional effect is much stronger than the ordinary ceramic tile, we fuse the ceramic and glass-ceramic together, through the glass refraction to the light to have a more vivid visual sense.

2.High strength, abrasion resistance, widely applications, unlimited using scope,including interior and outdoor decoration, wall and ground decoration, wet and dry dual-use

3.Patterns can be customized (personalized customize).Thousands of patterns including sea world, suspended wooden bridge, natural scenery, landscape painting, natural stone etc. Various sizes can be selected arbitrarily,or select complex designs of your own country decorating style

4.Never fade, easy to clean. Patterns will never fading, scrubbing the tiles freely,and color lasting as new.

5. Healthy and environment friendly, easy to clean. The product does not contain formaldehyde; non-toxic and tasteless; no radiation; corrosion resistance; anti-aging.Any dirt will take on a new look after gently rubbing.

6. Easily installation, once installed can move in ,the same simple as traditional ceramic tiles installation,once installed can move in

Machine technical parameters

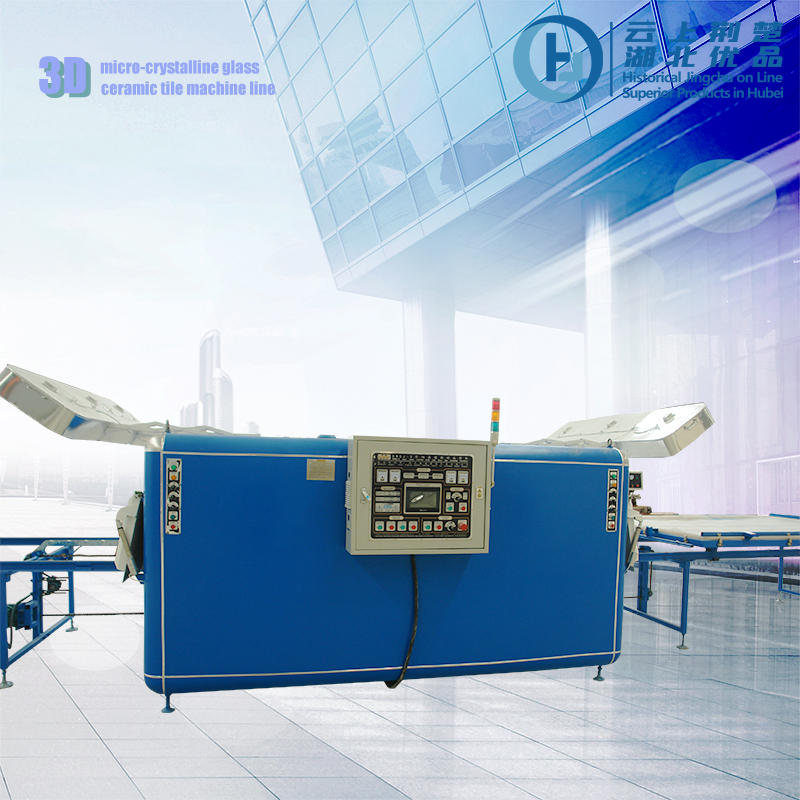

1-Forming machine

Voltage | 380V |

Power | 24.4KW |

Max working size | 1900mm×2500mm |

Processing thickness | 2-30mm |

Machine size | 10044mm×3170mm×1892mm |

Weight | 2250kg |

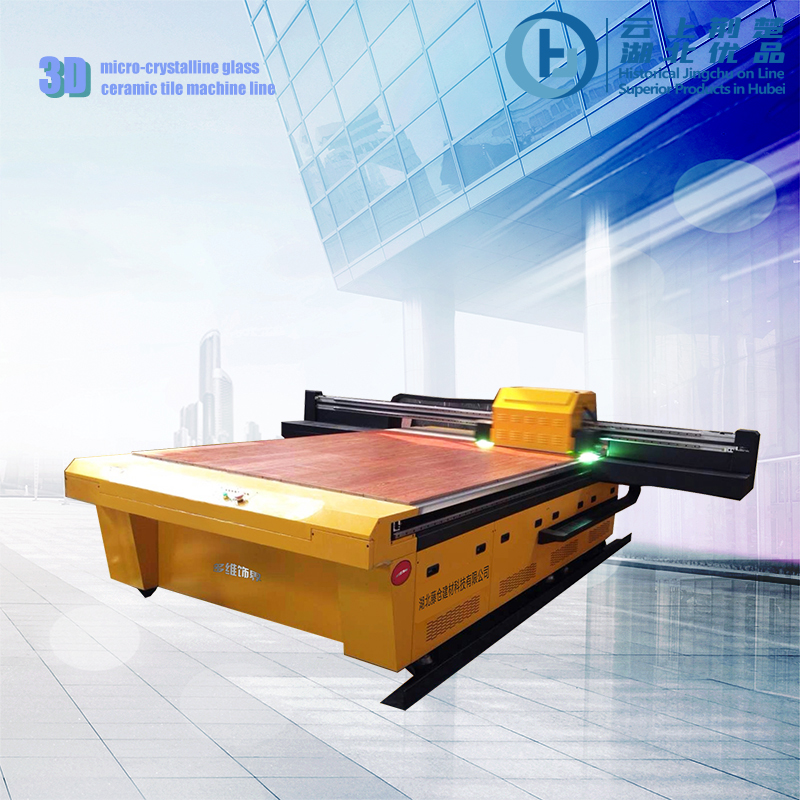

2-UV Flatbed Printer

Model | 2513 Epson UV Printer |

Print Size | 2500 mm * 1300 mm |

Print Head | 2 pcs Epson DX5 (3.5 pL) |

Head Lifespan | Within one year |

Colors | 8 colors (CMYK+WWWW) |

Print Height | 100 mm |

Work Platform | Tempered glass |

Weight Bearing | 100 KG |

Printing Speed | About 6m²/h with full color printing |

Print Resolution | 2880 dpi x 1440 dpi |

Software | Ultraprint |

Color Control | International ICC standard |

Curing System | 2 pcs UV lamps for fast curing |

Print Technology | Micro piezo on-demand inkjet printing |

Ink System | CISS (Continuous Ink Supply System) |

Print Direction | Unidirectional printing, bidirectional printing |

Head Protection | Automatic moisturizing device to prevent nozzle clogging |

Ink Stir | White ink automatic stir system |

Operation System | Windows |

Power Requirement | 110/220V, 50/60HZ, 3500W |

Weight | 1000KG |

Machine size | 3870*2160*1350 mm |

Packaging size | 4100*2250*1450 mm |

Packaging | Wooden case |

3-Grinding machine

Working speed | 1-5m/min | Grinding thickness | 2-30mm |

Max grinding size | 2000*2000 | Min grinding size | 40mm*40mm |

Machine size | 2300*1200*1500 | Voltage | 380v |

Power | 9.55KW | Weight | 600KG |

Production process:

printing machine print picture on the microcrystalline-glass

| |||||||

|

| Form by forming machine |

| Grind by grinding machine | → | test encasement delivered to warehouse | |

Traditional tiles | |||||||

Main application fields

a) For Home Decorations: TV background wall , sofa background wall, bedroom decoration, kitchen decoration, bathroom decoration, setting wall of hallway, children’s room, study room, the wall decorations of dining-room etc.

b) For Places of Business: companies, corporate image walls, storefront decorations, hotels, KTV, clubs, teahouses etc.

c) Public Space: setting walls of stations, wharfs, airport lounges, sports stadiums, theater, photographic studios, the booths, television studios, halls and meeting room’s ceilings etc.

Service Guarantee

1, remote training or send engineers to guide the installation, commissioning equipment, training workers to operate.

2, provide customers with complete production process and other technical information, training technical personnel.

3, provide raw materials procurement channels.

4,provide product installation and construction materials.

5, provide electronic product Atlas.

6.provide all accessories and parts of machines .

7, free to provide follow-up improvement of the project, such as the development of new products, technology upgrades.

CCCME Member

CCCME Member 0

0 Chinese Supplier

Chinese Supplier